Promo’s Collective Effort To “Demand Better” With Sustainable Packaging

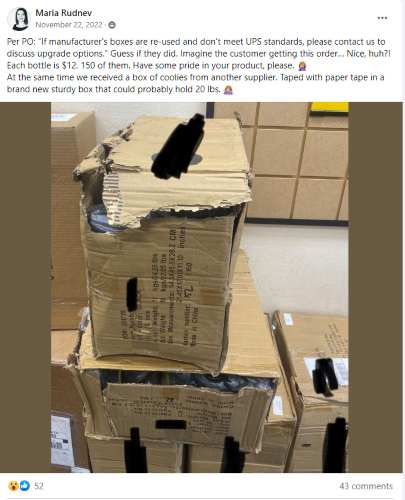

Your client’s order arrives, but it’s in a reused cardboard box that is falling apart. Are you just happy it arrived on time or are you reconsidering your commitment to reduce, reuse and recycle?

In November, when Maria Rudnev, president of Nevada-based distributor Pro-File Marketing, saw her packages, her first thought was: “Not again!”

So, she shared her frustrations on Facebook. Rudnev tells PPAI Media, “The PO clearly stated to contact us for upgraded packaging in case the original manufacturer's boxes were reused. What else can we put on the PO to make it clear to the supplier that we don't mind paying extra so this doesn't happen?”

Luckily, Rudnev’s client was local, so the orders came to her first. “I'm terrified to think what would happen if this went directly to the client,” she says.

Rudnev isn’t the only one being surprised by reused packaging.

Rama Beerfas, MAS, CTSM, owner of California-based distributor Lev Promotions, says, “Suppliers need to realize that the box reflects on the distributor and to ship it in a way that doesn’t look questionable, weird or cheap.”

Low-quality packaging wastes time and money. It also exasperates finite resources and stirs frustration in the industry. The only solution is beginning with the end in mind – with high-quality, sustainable packaging.

What Is Sustainable Packaging?

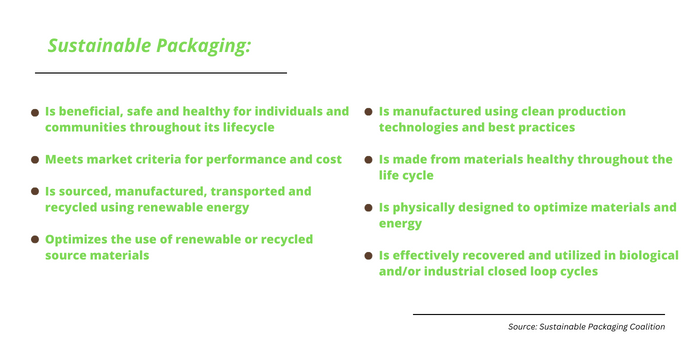

Over time, sustainable packaging reduces its environmental footprint. Ingredients, production processes and reusability define the practice. But it also considers social and economic factors.

According to the Sustainable Packaging Coalition, packaging can become “a closed loop flow of packaging materials in a system that is economically robust and provides benefit throughout its lifecycle.”

Heidi Reimer-Epp, CEO and co-founder of Canada-based supplier Botanical Paperworks, says it’s important to create a corporate and personal definition of sustainable packaging “which considers all aspects of sustainability.”

Barriers to reducing packaging waste exist, however, and “two big ones are cost and availability,” she says.

“It's often more costly to wrap products in paper than plastic because the process is slower and more labor-intensive. Sustainable packaging can come with a higher cost. Paper-based packaging can make a package heavier, thus increasing shipping costs and greenhouse gas emissions. We’ve seen the supply of cardboard boxes and paper mailers get tighter as online shopping exploded during the pandemic and as people switched to paper-based packaging.”

With 2025 fast approaching, a milestone year for sustainable packaging promises, many companies are struggling to meet goals against financial, technical or operational obstacles. In 2021, Gartner predicted that 90% of organizations will fail to meet their 2025 sustainable packaging goals.

Suppliers Define Sustainability For Themselves

Reducing waste is an industry-wide issue. Reimer-Epp says, “The responsibility of reducing waste falls to us as individuals and as companies. There is an urgency to this work, and we are being called by the media and customers to do better.”

Botanical PaperWorks offers plantable seed paper belly bands, boxes and box filler. “All are great packaging solutions because the seed paper itself is made from paper waste and then the recipient can plant the band, box or filler and grow flowers leaving no waste,” says Reimer-Epp.

For suppliers looking to make their packaging more sustainable, Reimer-Epp suggests meeting one or more of the following criteria: made from waste, can be recycled, or can be reused.

“Next, distributors and suppliers alike can look at their packaging from this perspective and find inspiration for change,” she says. “For example, using seed paper tags on garments instead of a glossy, non-recyclable tag. Packaging is used for products but also for marketing materials, so sending a catalog QR code on a plantable postcard instead of mailing a printed catalog. Finally, involving team members from all areas and levels of the company is a great way to generate a diverse set of ideas and to drive engagement.”

Texas-based supplier Metropak has a wide range of degradable and recycled poly products, including ReThink poly bags and mailers available in 50% and 90% recycled content. The company also produces reusable bags made from certified recycled (rPET) water bottles and paper bags made with 100% recycled post-consumer content.

We continue to bring new options to our distributors,” says CEO Eric Grossman. “We spend the time and money required to have all our leading sustainable products certified. Aside from living and operating as sustainably as possible by encouraging recycling within the company and converting 90% of our scraps into new materials to produce our products, leadership stays informed by attending conferences on recycling and sustainability, regularly.”

Grossman says it’s important to incorporate recycled content in as many products as possible at the highest level without sacrificing quality and reusability. “They have often called the products we produce “trinkets and trash,” and we do produce a lot of products that end up being disposed of. I believe we need to make these products as reusable and recyclable as possible so that they can have another life. It would make customers feel better about using them as marketing tools.”

Distributors Decide Who To Work With

Consumers care deeply about sustainability. According to the Businesswire, globally, sustainability is rated as an important purchase criterion for 60% of consumers. In the US, it is 61%. More than one-third (34%) of the population is willing to pay more for sustainable products or services.

Jamie McCabe, president of Canada-based distributor McCabe Promotional Advertising, says sustainable packaging is important for every product, but especially sustainable ones. “Offering a sustainable piece in landfill-bound packaging jeopardizes both the message and environmental impact of the sustainable piece.”

For most distributors, packaging and shipping is out of their control. McCabe says, “Sustainability begins at the source of the product — with the manufacturer and supplier. Our control is limited to communication and prioritization of sustainability wants with suppliers and the refusal to purchase products that don’t meet sustainability objectives.

“This lack of control also extends beyond the distribution of a product. So often, sustainable packaging is only successfully executed when it is diverted from landfill, which requires the end user to have access to and knowledge of appropriate recycling streams and then to action disposal appropriately.”

To end users, packaging is the first impression of a brand. “Packaging is a great medium to improve the messaging of sustainability to an end user and build trust that the product/brand they are receiving aligns with an end user's core values,” he says. “The packaging is the first interaction the end user has with the offering, so it is critically important that the messaging and overall experience is consistent with the item and marketing objectives.”

Tara Milburn, president of Nova Scotia-based supplier Ethical Swag, says a sustainable product in poor packaging is like eating a salad for dinner, but a double fudge brownie with ice cream for dessert.

“Sustainable packaging is extremely important for us, always, but we do recognize we need to accept progress over perfection,” she says. “When it comes to eco products, it is particularly important.”

McCabe says the path forward is education. “[We can become leaders] by investing in education for suppliers and distributors in how to successfully utilize and implement sustainable packaging,” he says. “Additionally, we can create industry standards that suppliers and distributors can strive to achieve and transparent reporting on the use of sustainable packaging within our industry.”

Vetting supplier partners is also key to reducing packaging waste. “At Ethical Swag, we vote with our purchase orders,” says Milburn. “We work with our suppliers and request sustainable packaging on all our POs. We monitor how products are shipped and stop using suppliers that over package and/or use excessive plastic.

“We need to demand better, vote with our dollars/POs and make it a priority if we want to see change.”

The Promo Industry Should Lead

Liz Haesler, chief merchandising officer at Pennsylvania-based supplier PCNA, believes the promo industry can become a leader in sustainable packaging. “Our industry can set the trends — there are so many formidable players in ecommerce and retail that still have not figured this out,” she says. “We can make a commitment to develop packaging that supports the earth and our product.”

PCNA has set an aggressive target for all packaging to be sustainable by 2024. The company is utilizing all recycled and biodegradable poly bags while working to eliminate as much poly as possible.

She says, “In addition to designing our own packaging, we’ve also hired a packaging engineer to continue to aid our efforts to design and manufacture the most sustainable packaging possible, as well as ship it in the most effective manner to continue to reduce our carbon footprint.”

For Haesler, striking a balance between what’s needed for safe transportation and what’s extra packaging is critical. These efforts spark creativity and unique package designs.

“All new hardgoods products will have packaging designed (like a window on the box) to allow for easier digital printing—a much cleaner method overall—to reduce reliance on traditional transfer, silkscreen and pad print,” says Haesler.

“The creative aspect comes from the rapidly changing availability of new materials. The movement towards more natural solutions, biodegradable solutions as well as figuring out other creative ways where packaging can serve an additional purpose before the end of its life, rather than being tossed directly in the trash.”