Industry Companies Retrofit Manufacturing To Provide Critical Supplies

As the coronavirus continues to spread, the demand for medical supplies to protect health care workers has spiked, threatening to exhaust available supplies.

In response, several companies within the promotional products industry have stepped up to help fill the critical void. Among them is Fey Industries, Inc.(PPAI 113944, S8) in Edgerton, Minnesota, which has a manufacturing facility with the capability to provide RF heat sealing, thermoforming, injection molding and other techniques. “With President Trump invoking the Defense Protection Act easing the way for additional manufacturers to help, we are looking to offer manufacturing assistance/capacity to medical product firms to help produce more product and protect our medical personnel, EMTs, etc.,” says President Mike Fey. Fey and his team have been exploring several avenues on the state and federal level, including many of the medical companies in the Minneapolis/St. Paul area. This morning the company presented prototypes to a local health care system for face shields and gowns for health care workers. Once an order is received, the company is prepared to turn out 10,000 pieces by end of the week.

Fey’s Marketing Manager Beth Friese says the new project fits perfectly with the company’s official purpose: Brightening the world through our actions.

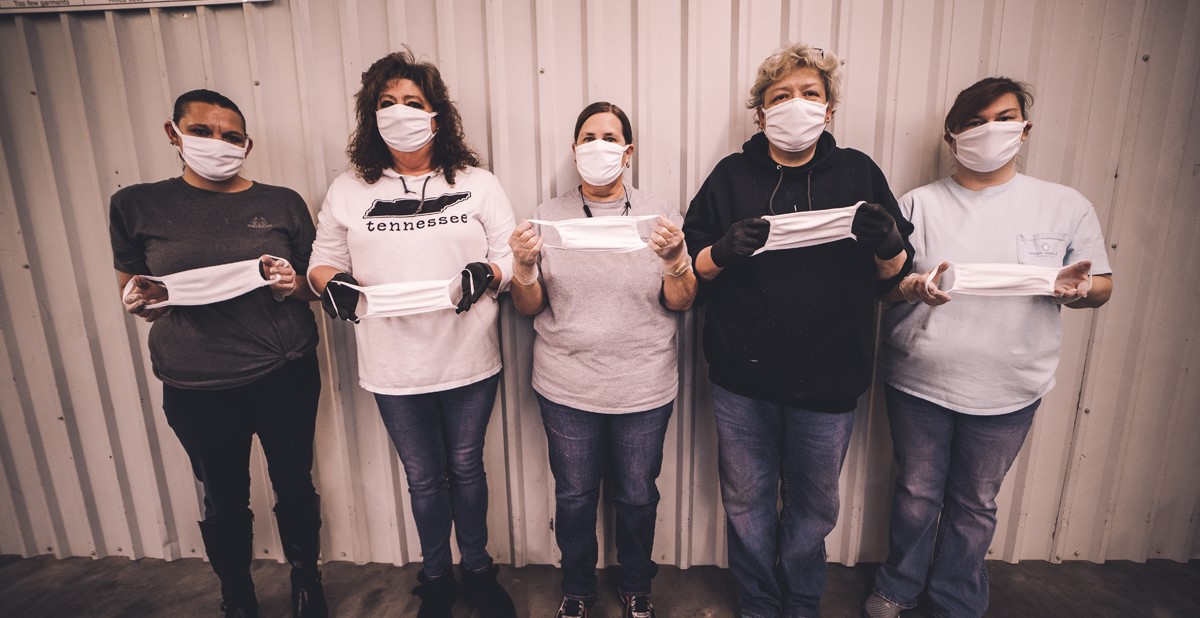

ABC News reports that Hanes is retrofitting its factories to make medical face masks for health care workers. The company does business in the promotional products industry as Hanes/Champion (PPAI 191138, S10) based in Winston-Salem, North Carolina. President Trump announced the company’s efforts at a press conference on Saturday. The news report said Hanes expects to ramp up to production of 1.5 million masks weekly and is working with a consortium of companies including suppliers Sanmar (PPAI 110788, S16), Fruit of the Loom (PPAI 133342, S5) and AST Sportswear (part of Bayside Made in America PPAI 213725, S4).

“This came together really fast,” says Jeremy Lott, president of Sanmar. “Our first conversation about it was on Thursday and here on Tuesday, we’re beginning production on a product none of us had made before. It’s a tremendous level of effort. Whatever it takes to get this done, let’s do it right now. While we’re also fighting this challenge to our business that is existential, nothing is more important than this effort as the need is so dire.”

Together, the consortium is expected to produce five to six million masks weekly using HanesBrands’ design and patterns, the company said in a statement. “The company’s supply chain and product development experts created technical product specifications, including product chemistry, and samples of cotton masks in coordination with the U.S. Department of Health and Human Services that were approved by the FDA.”

Lott adds, “Companies that are friendly competitors in normal times understand how important it is to band together and collectively be much stronger. And more companies are coming onboard. This is a story of an industry coming together. People who have the ability to do so are reaching out to help. This is us answering an urgent humanitarian need and our greatest hope is that they put us out of the mask business very soon with the development of a vaccine.”

3M, parent company of 3M Promotional Markets Department (PPAI 113638, S11), has doubled its global output of N95 respirators to an annual rate of more than 1.1 billion per year, or nearly 100 million per month since the COVID-19 outbreak, according to news reports.

The Mankato, Minnesota-based company currently manufactures more than 400 million N95 respirators annually in the U.S., most of which are being directed to health care facilities battling the outbreak. The company also manufactures respirators at locations in Europe, Asia Pacific and Latin America.

In addition, 3M is also reportedly maximizing production of other products for use in the COVID-19 response including hand sanitizers, disinfectants and filtration solutions as the pharmaceutical industry works to find a vaccine to fight the virus.

Suppliers and distributors are encouraged to use PPAI’s new status page to post and view updates and status reports regarding supplier company’s operations.