The Long March: Promo’s Ongoing Retreat From China

It’s hard to make branded apparel without cotton, and the cotton has to come from somewhere.

The where has never been of greater importance to the promotional products industry.

Accusations of forced labor used in the production of cotton and other goods and materials in China, particularly in the Xinjiang province, are credible and concerning. Recognizing the human rights implications and its impact on creating a just, equitable supply chain, the industry has moved quickly to ensure that the goods it offers are compliant and responsibly sourced.

Even before the Uyghur Forced Labor Prevention Act went into effect in June 2022, the promo community had begun to increase scrutiny and develop deep levels of control in its supply chain and, in many cases, began moving to diversify sourcing outside of China.

Quitting China

Last year, at the 2022 PPAI Product Responsibility Summit, a poll of the industry compliance professionals in attendance found that 83% were looking to move their production out of China. That the sentiment is so strong isn’t surprising, but moving sourcing away from China represents significant challenges.

Businesses’ decision to find alternatives to production in China is driven by a range of issues:

- Tariffs

- Supply chain disruptions

- The country’s rigid COVID lockdowns

- Geopolitical tensions

- Forced labor allegations

However, decades of investment on the part of industry and the Chinese government have built a network of production infrastructure – factories, materials vendors, a skilled workforce, transportation lines and port facilities, etc. – hard to replicate anywhere else.

Laws like the UFLPA and export control rules, which prohibit U.S. companies and engineers from assisting in the production of certain types of semiconductors, place limits on what business can be done in China. But China itself has introduced legislation providing for retaliation against companies that comply with these sanctions.

Isaac Stone Fish, founder and CEO of Strategy Risks, a consultancy helping companies manage and reduce their risks doing business in China, warned attendees at the 2022 Summit, “For so long, China was the source for most of your materials. In the medium and long term, that’s likely to be a liability.”

Cotton Concerns

Cotton leads these challenges. President Biden signed the UFLPA into law in December 2021. The legislation, which received bipartisan support in Congress, bans imports from China’s Xinjiang Uyghur Autonomous Region under the presumption that all goods made in whole or in part in the area are produced with forced labor.

“In 2022, the XUAR produced roughly 90% of China’s cotton, making much of Chinese cotton product exports potentially susceptible to the UFLPA,” Stone Fish says. “That figure does not include textile products produced outside of Xinjiang with the participation of Uyghur laborers, but the UFLPA applies to such products as well.”

Complicating the exit from China, Chinese cotton is exported abroad and may be found in products produced in other countries.

“Chinese textile companies have been expanding their activities and presence to other countries in Southeast Asia and South Asia,” Stone Fish says. “Vietnam, for example, is an important hub for Chinese textile products. These countries also import textile products, such as thread, from China. These more complex international supply chains can obscure the source of components of textile products. Companies that relocate their sourcing outside of China still need to keep track of their entire supply chain and make sure they are not purchasing Chinese cotton through a company based in a third country.”

Importers are cutting back on material brought in from China, and what continues to come from the country is under strict scrutiny. But cotton tracing is a highly specialized and difficult process, and even textiles purchased from other countries may be found to have traces of Chinese-grown cotton woven in.

“The risks cannot be eliminated completely,” Stone Fish says. “The textile industry in China is extremely exposed to forced labor and other human-rights violations in Xinjiang. As a result, all textile products originating in China run a substantial risk of exposure to Xinjiang cotton and labor.”

Promo Puts Measures In Place

The straightforward answer to complying with the UFLPA is to source cotton somewhere other than China. The 2022 Summit poll is evidence of an openness in the promotional products industry to move production outside of the country, and industry companies navigating through the challenges of cotton sourcing are working with suppliers with which they have long, established relationships, putting new inspection practices in place and transitioning away from China.

“SanMar believes that anyone involved in the production of our products should be treated fairly and in accordance with relevant labor laws,” says Jeremy Lott, CEO of Issaquah, Washington-headquartered apparel supplier SanMar. “Several years ago, SanMar dramatically reduced sourcing volumes from China. The limited number of products we do source form China are from long-term, trusted suppliers who are leaders in the textile industry. They understand the issue and the risk sourcing from XUAR would pose to their business, and they have proven their traceability processes to ensures no inputs are from XUAR.”

Pierre Montaubin, senior vice president of product management and sourcing at Clearwater, Florida’s Koozie Group, which uses cotton in bags and other items, says, “Respect for human rights is a fundamental value of Koozie Group, and we aim to identify and address any risks in our supply chain. As best practice in 2020, we made the decision to find alternative sources outside of China for production of cotton goods. As a result, all our cotton products are now being sourced from Bangladesh, Pakistan and India. We use third-party audits and supply chain mapping to ensure any cotton we purchase is not sourced from the Xinjiang region of China.”

Next Level Apparel, located in Torrance, California, recently announced partnerships with textile manufacturer Grupo M, based in the Dominican Republic, to move its production closer to the North American market, as well as forensic science company Oritain to verify the origin of products and raw materials.

“As part of our commitment to delivering high-quality, responsibly sourced apparel, we work to ensure the integrity of every fabric we use,” says Randy Hales, CEO of Next Level Apparel. “That means we comply with robust sourcing standards that are endorsed by leading associations in the industry and hold our suppliers to the same high expectations, using isotopic testing as an important safeguarding mechanism.”

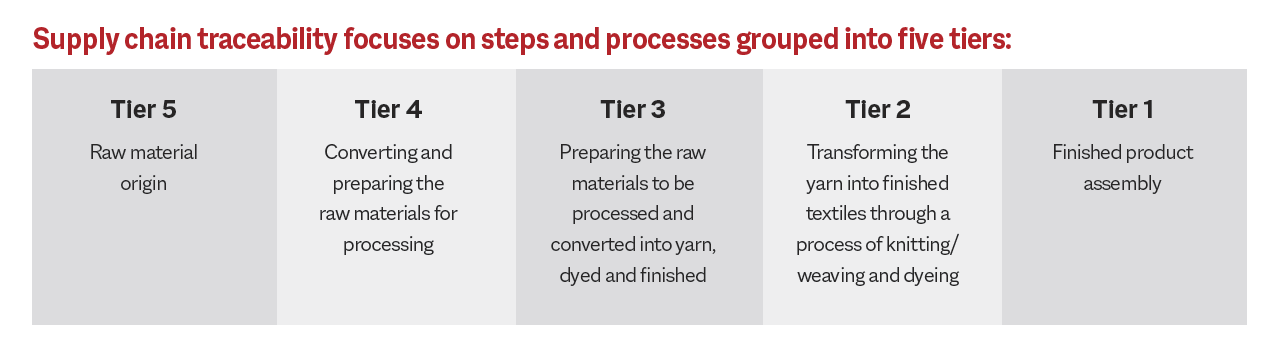

Cheron Coleman, vice president of private brand product development and global supply chain at Trevose, Pennsylvania-based supplier alphabroder Prime Line, says, “We have implemented a material traceability process, from dirt to shirt, for our private brand products, which ensures that the inputs that make up all the parts of a finished product have verifiable documentation bridging back to their production. We trace our total supply chain from raw material origin through finished product assembly.”

In April 2022, New Kensington, Pennsylvania-based Polyconcept North America launched ProudPath, an online platform designed to help distributors navigate social and environmental responsibilities and reflect the company’s policies on responsible sourcing, including diversified manufacturers and local materials.

“At PCNA, we moved 90% of our cotton products outside of China,” says Liz Haesler, PCNA’s chief merchandising officer. “It’s the right thing to do, but it hasn’t been easy. We’ve mostly moved to India and Bangladesh, where we can make sure that we’ve got local cotton resources.”

For the remaining 10% and the hard goods it continues to procure in China, PCNA has a team of 80 people in the country who evaluate the vendors the company works with, Haesler says. “They actually go and do inspections and make sure that the factory code of conduct that they have signed is being followed so that we are responsibly sourcing.”

Inspect, Inspect, Inspect

The promotional products industry is devoting considerable time, expertise and effort to ensuring that the cotton and other goods it imports are compliant with the UFLPA and not the product of forced labor.

“We began tracking the cotton issue in 2019, when we were made aware of reports of human rights abuses occurring in XUAR,” says SanMar’s Lott. “Over the next several years, we began a series of supply chain mapping exercises, working closely with our suppliers, to identify where our products are sourced and ensure no finished products or inputs to products are made in XUAR or by entities named on the UFLPA Entity List.”

These inspections and standards extend to the partners and vendors industry companies do business with, as well.

“We do not source cotton directly; therefore, we require all our suppliers to include raw material certifications with each shipment,” says Next Level’s Hales. “Further, we comply with robust sourcing standards that are endorsed by leading associations in the industry, hold our suppliers to the same high expectations and use isotopic testing as an important safeguarding mechanism.”

Making The Move

The exit from China has been one of measured progress for most companies in the promotional products industry, although not uniform across product categories, as production alternatives for some goods may be more readily available than others.

Approximately 53% of Koozie Group’s total production expenditures are in Asia, although the company is making progress in reducing its reliance on China.

“Of the spend in Asia, 90% of it is still coming from China. In 2016-2017, it was 97%,” Montaubin says. “We have moved some production from China to Vietnam, Bangladesh and India over the past few years. We have looked at Mexico as an alternative source, but there is still a big price gap between Mexico and China despite the cheaper freight.”

Haesler says PCNA is looking for opportunities in other countries, not just because issues in China with cotton but also to diversify as part of the company’s ProudPath initiative. In particular, the company is exploring alternatives for certain hard goods categories that currently come primarily out of China.

“The piece of it that will continue to be a big problem for us – or opportunity, to be honest with you – is drinkware, which is an $8 billion industry, and it’s all coming out of China,” Haesler says. “Tech is another area where almost the whole industry is located in China. We have moved cables and some things to Vietnam. Also, some of the drinkware factories we work with are exploring U.S. production, as well as opening a factory in Mexico.”

Closer To Home

As China’s appeal as a source of production wanes, an alternative showing promise for importers is to bring their manufacturing bases closer to the U.S. border. Nearshoring production has been behind several promo companies’ decisions to establish facilities in Mexico and Latin America.

A number of industry companies, including Augusta Sportswear, MAC Specialties and Proinnovative, already operate facilities in Mexico.

“We recently announced partnerships with GK Global and Grupo M as part of our move toward sourcing 100% U.S. cotton for our entire apparel line,” says Next Level’s Hales. “Nearshore fabric supply has not fully aligned with the current demand. We will continue to support our nearshore partners and grow alongside them as we work to bring our fabric production closer to home. Strengthening our nearshore partnerships will continue to benefit our supply chain.”

The push to nearshore production has also factored into some large business moves in the promotional products industry. At The PPAI Expo 2023, Boston-based supplier HPG announced that it had acquired fellow supplier Evans Manufacturing, headquartered in Garden Grove, California. HPG CEO Chris Anderson highlighted Evans’ operations in Mexico as a factor in HPG’s decision to make the acquisition, as its strategic initiatives include nearshoring as much of its production as possible.

Lessons For Promo

Promo industry companies have invested time, effort and money into creating and managing responsible, compliant supply chains, and the process has brought insight as well as progress:

“We believe our global cotton sourcing strategy with our partner suppliers maintains an ethical and compliant position and better aligns with our corporate values,” says Coleman of alphabroder Prime Line. “We have found many attractive alternatives to China-sourced cotton and will continue to partner with suppliers sourcing verified, ethically sourced raw materials.”

Hales says, “Banned cotton is a challenge across the apparel industry that we’ll continue to face until every party truly commits to eliminating these cotton sources from the total supply chain. We encourage those in the industry who are unable to transition to nearshore sources to implement safeguarding measures, such as requiring certifications and testing.”

SanMar’s Lott emphasizes that industry companies remain cautious and aware of the issues surrounding China-sourced cotton. He says, “Make sure you are mapping your supply chain and collecting the appropriate documentation to prove where your products were made. We must know our suppliers, know our supply chain and be vigilant in our efforts to uphold human rights around the world.”

Khattak is the senior digital editor at PPAI.