Licensed To Chill

Taiga Coolers

Taiga ups the custom cooler game with patented technology

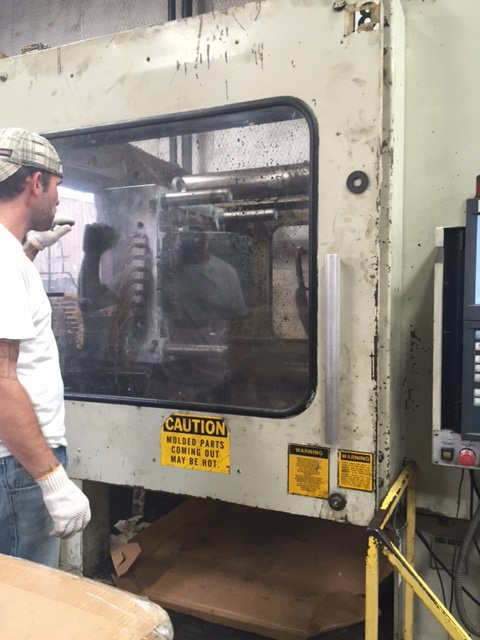

John Hohenshelt, left, and co-owner Adam Artho are leaving their mark on the custom cooler business.

Whether you’re camped out in a deer blind or cruising on the lake, hard-sided coolers with incredible ice retention are a hot commodity that’s become an even hotter trend. Dallas, Texas-based, veteran-owned supplier Taiga Coolers has turned up the heat on the competition by introducing coolers with a patented twist on customization.

The cooler craze was in full effect when John Hohenshelt and Adam Artho met through a mutual friend in 2013. Though each was pursuing a career in other industries, the two came together to launch Taiga officially in 2014, determined to offer a unique version of a popular product.

“We are a custom cooler company with a standard product line,” says Hohenshelt. The product range is limited—coolers and tumblers are the supplier’s bread and butter—but there’s a good reason for that.

“While everyone else is doing rotational molding [for hard-sided coolers], we have patented a method of injection molding, putting the logos into the plastic,” he says. “In the promotional products industry, everyone wants a ‘Brand Y’ product—but they are getting very little long-term branding from a very expensive item” when the name-brand coolers aren’t customized with a client’s logo, color or name.

Taiga’s main product differentiator, says Hohenshelt, is the ability to mold customer logos into the front of coolers using the customer’s company colors. “All of this is permanent on the cooler, so the logo is seen every time a person goes into the cooler for a beverage.”

The development process—including the development and manufacture of injection molding equipment—took roughly eight months, says Hohenshelt. Taiga’s hard-sided coolers come in standard white and tan and in camouflage shades, but the company has plans to include more styles, particularly for collegiate fans. “We are in the process of acquiring collegiate licensing,” says Artho. “We’d like to create collegiate camouflage designs.”

The stainless steel tumblers that are proving just as popular weren’t initially on the owners’ radar, says Hohenshelt. But on a lark they purchased a container-load of the drinkware, and approached decorating with the same desire to be unique in the industry.

“We laser etch and powdercoat the tumblers, and we also designed a lid for ease-of-use,” says Hohenshelt. “Many customers don’t know the difference between laser etching and pad printing. Laser etching lasts for the life of the product, whereas pad printing will eventually wear off. We will also powdercoat tumblers in custom colors and then laser etch logos so the stainless steel shows through.”

Read on to learn how Taiga’s custom coolers are created.

A machine operator waits for the custom injection molding machine to finish before releasing the cooler.

Taiga’s injection molding process allows for images such as logos and brand names to be incorporated directly into the cooler’s plastic shell.

Cooler shells bearing Taiga’s company logo are stacked in preparation for assembly.

About Taiga Coolers

Principals: John Hohenshelt, Adam Artho

Founding Date: 2013

Facility Size: 15,000 combined square feet between three facilities: one in East Texas, and two in the DFW Metroplex

Notable Achievements: Taiga, which is veteran-owned and produces its custom products in the U.S. (Texas), has provided custom coolers and tumblers for the Chris Kyle Memorial Benefit