Etching Excellence

Advance Corporation celebrates 75 years of producing eye-catching awards

Going from hot to cold in a matter of minutes isn’t always an appealing characteristic—unless you’re talking about custom-fired art glass. In that case, supplier Advance Corporation in Cottage Grove, Minnesota, is turning out some very appealing examples.

Founded in 1941 by William and Francis Lorenz, and a member of PPAI since 1976, Advance Corporation (UPIC: ADVANCE) first operated as a rubber stamp and engraved sign manufacturer in St. Paul. Today the company, led by second-generation owner Glen Lorenz, also manufactures Braille building signage and donor recognition products through its Braille-Tac™ division, and metal dies for foil stamping and embossing/debossing through its magnesium die division.

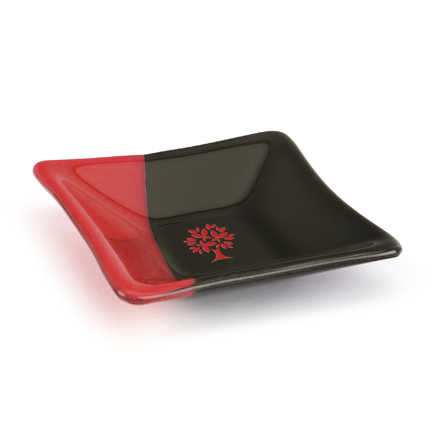

But it’s the art glass awards produced on-site that put a gleam in many customers’ eyes. “The beauty of artistic glass is that the products are one-of-a-kind works of art. The products represented are handcrafted by highly trained artisans,” says Kathy Wilson, vice president of sales and marketing for Advance.

“Advance has been witness to a major shift in the industry,” says Wilson. The shift, she says, is moving away from a traditional type of award to a more customized, unique style that is designed specifically for a recipient or program.

“This one-of-a-kind award feature is the latest trend and a perfect fit for Advance. Our niche is to offer a wide array of standard products that can be made to order as pictured, or customized in-house to meet the needs of our customers,” she says.

Advance’s house designers work closely with the sales team to create conceptual layouts that provide a virtual illustration of the product options, and newer equipment allows the supplier to offer larger format products with shorter lead times. “Our skilled team of craftsmen has attended some of the best technical trade schools and universities,” Wilson says.

The top three products among Advance’s clients currently are traditional wall-mounted awards, framed and matted wall awards, and full-color metal or acrylic awards. “Our perpetual awards and donor wall units are gaining in popularity,” adds Wilson

“We produce all the standard items pictured in our catalog in our manufacturing facility in Cottage Grove,” she says. “We purchase crystal and glass blanks that we personalize, but all of our artistic glass awards are made from blank sheet stock which is cut, fused, slumped and etched in-house. All of our graphic design is also done in-house.”

Read on to learn how pieces from Advance Corp.’s artistic glass desk accessory collection are crafted.

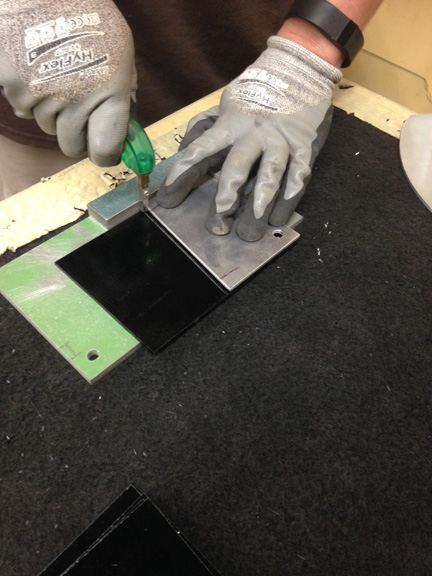

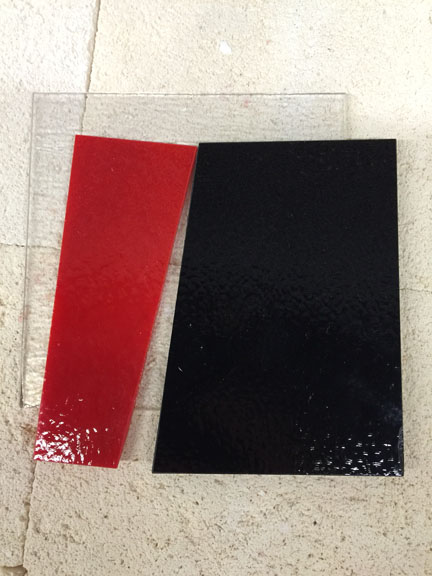

- The production process uses full layers of artistic glass, depending on the customer’s choice of color. Pieces are hand-cut and trimmed to size.

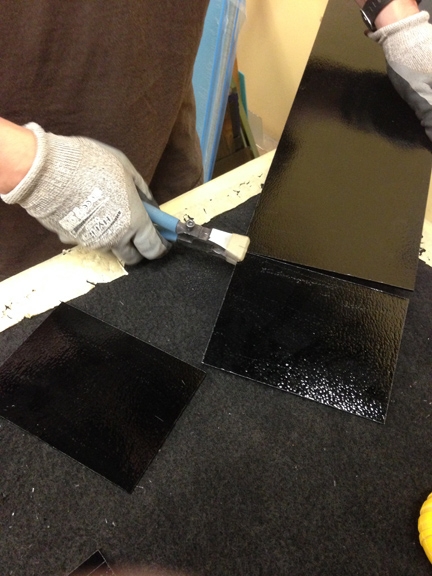

- After the pieces are trimmed, they are placed in a kiln for the fusing process. The artistic glass is brought to a specific temperature so the two layers of glass become one. The part is then placed on top of a form and placed back inside the kiln where it is processed a second time until the glass falls into the shape of the form. This fusing and slumping step is a two-day process.

- The customer’s artwork is then transferred onto the surface of the artistic glass using Advance’s sandblasting process. If the customer chooses colorfill, the cavity is sandblasted deeper to contain the colorfilling ink. The finished piece is then cleaned and placed into a two-piece gift box with protective precision-cut foam.

About Advance Corporation

William and Fran Lorenz, Advance Founders

Founding date

1941

Principal

Glen Lorenz, owner

Number of orders filled per year

10,200

Notable accomplishments

Recipient of over 80 PPAI Supplier Achievement Awards in the past 25 years

Size of production facility

50,000 square feet

Number of employees

60-65

Types of specialized equipment

Laser-cutting equipment

Art glass warm shop

Resin casting equipment

Warm glass shop with kilns and sandblasting units

MetalPhoto® processing equipment

Industrial ovens

Nitric and ferric acid etching equipment